About

Condensing units are assembled devices which are composed of the compressor and condenser. The condenser can be air or water-cooled, which greatly affects on the dimensions of the unit and unit look. Condensing units are manufactured in a wide range of cooling capacity and are characterized by their reliability and ease of use.

Air cooled condensing units

Air-cooled condensing units are primarily intended for outdoor use. Can be connected to one or more evaporators. Mostly they are intended for synthetic refrigerant (HFC), but also may use a natural refrigerant such as propane.

Offered compressors are hermetic scroll and semi-hermetic reciprocating compressors from reputable manufacturers. May be incorporated one or more compressors (up to 4) and can be connected in series or parallel depending on the installation site of the device. Condensers are the aluminum micro-channel condensers which reduces weight and refrigerant charge.

Offered fans are axial fans from renowned manufacturer Ziehl Abegg. It is recommended to use fans of the last ZAplus generation, which are characterized by high efficiency, high air flow and low noise, but also are availavle other series of axial fans of the same manufacturer, depending on customer needs.

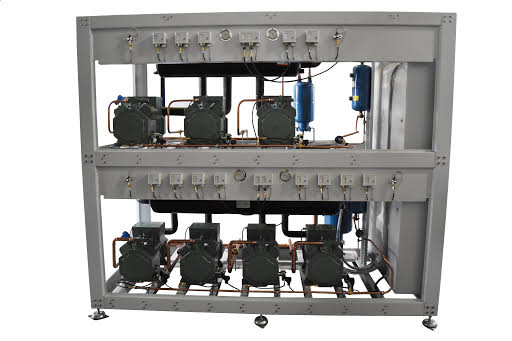

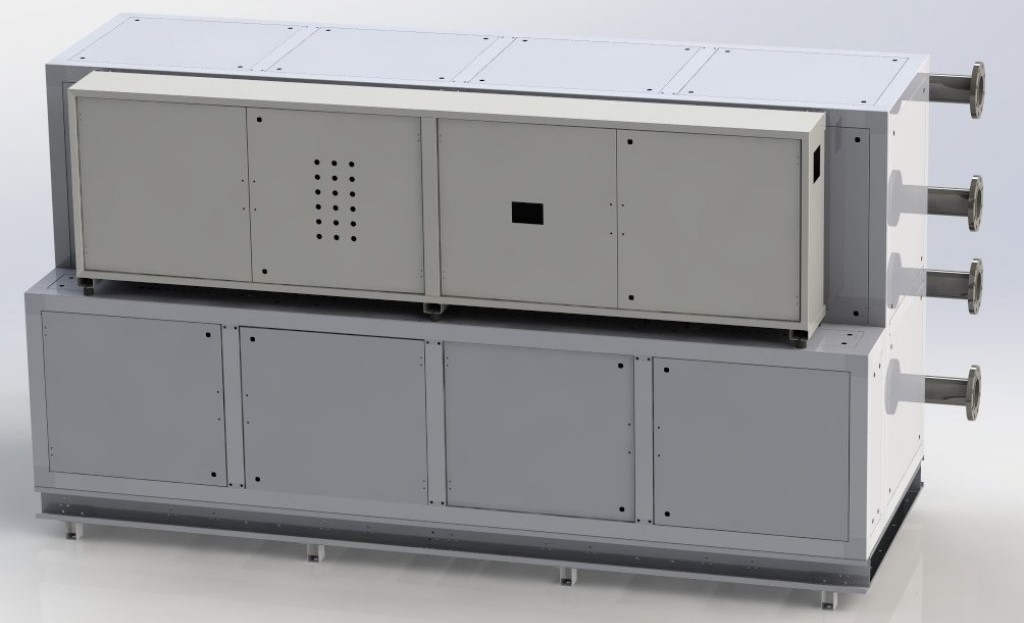

Water cooled condensing units

Water-cooled condensing units are assemble of compressor and a water condenser. Units can be for outdoor and indoor installation. The most commonly are used synthetic refrigerants (HFC). Units can be also made for for natural refrigerants such as propane.

A wide range of compressors is available, as well as at the air-cooled condensing units. Water condensers are plate heat exchangers which are characterized by compact dimensions, high heat transfer coefficient and low pressure drop. in the unit can be installed a three-way valve on the water side ensuring safe and proper operation of the device.